When working in hazardous environments, explosion proof cable glands for hazardous areas are essential for ensuring safe and reliable electrical connections. These specialized fittings, along with their accessories, protect cables from damage while preventing sparks or heat from igniting flammable substances. In this comprehensive guide, we’ll explore the features, applications, and benefits of explosion proof cable glands, and how to choose the right ones for your project.

What Are Explosion Proof Cable Glands?

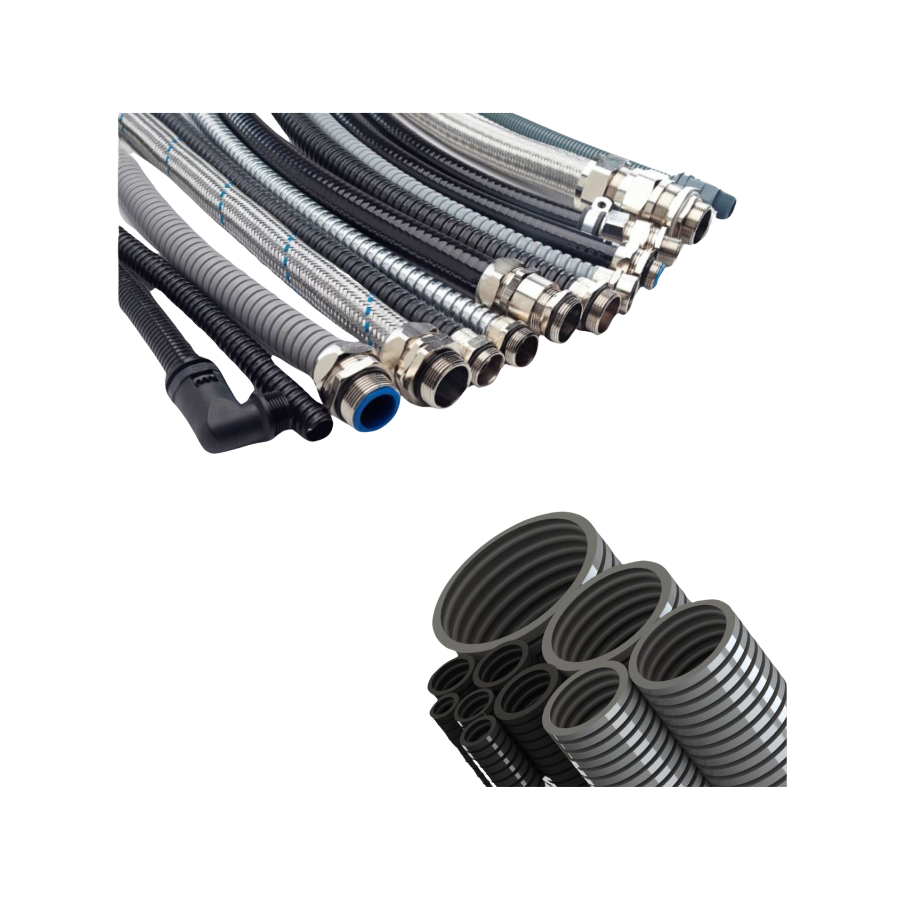

Explosion proof cable glands, often called ATEX certified cable glands, are fittings used to secure cables entering electrical enclosures in hazardous areas. They provide a flameproof seal, preventing the passage of gases, dust, or flames while maintaining the integrity of the electrical system. Made from materials like brass, stainless steel, or nickel-plated brass, these glands are certified for use in Zone 1, Zone 2, Zone 21, and Zone 22 environments.

Key Features of Explosion Proof Cable Glands

Here’s why flameproof cable glands for oil and gas are a top choice:

Sealing Performance: Achieve IP68 ratings for waterproof and dustproof protection.

Wide Temperature Range: Operate reliably from -60°C to +300°C.

Corrosion Resistance: Nickel-plated brass or stainless steel options resist saltwater and chemicals.

Compatibility: Suitable for all type of armored, unarmored, and braided cables.

Essential Accessories for Explosion Proof Cable Glands

To maximize safety and performance, pair your cable glands with these accessories:

Shrouds: Protect glands from dust and UV exposure—PVC or silicone options available.

Locknuts: Ensure a secure fit, available in brass or stainless steel.

Earth Tags: Facilitate grounding to prevent static buildup.

Sealing Washers: Enhance IP rating by providing an extra layer of protection against moisture.

For instance, a recent project in a Middle Eastern refinery used our waterproof explosion proof cable glands with silicone shrouds, extending the system’s lifespan by 20% in extreme desert conditions.

Applications of Explosion Proof Cable Glands

These glands are critical in various industries:

Oil and Gas: Secure cables in offshore rigs, refineries, and pipelines.

Marine Environments: Protect against saltwater corrosion in shipyards.

Chemical Processing: Used in plants handling flammable liquids or gases.

Power Generation: Ensure safety in nuclear or coal-fired power plants.

How to Choose the Right Explosion Proof Cable Glands

Selecting the best cable glands involves these steps:

Cable Type: Determine if your cables are armored or unarmored to choose the right gland type.

Thread Size: Match the gland’s thread (e.g., M20, M25) to your enclosure.

Environmental Conditions: Opt for stainless steel glands in corrosive environments.

Certification: Ensure ATEX certification for compliance.

Accessories: Include earth tags and shrouds for added safety.

Common Challenges and Solutions

Challenge: Improper sealing leading to water ingress.

Solution: Use sealing washers and ensure proper torque during installation.Challenge: Cable gland corrosion in marine environments.

Solution: Choose nickel-plated brass or stainless steel glands.Challenge: Static electricity buildup.

Solution: Install earth tags to ground the system effectively.

Why Choose Our Explosion Proof Cable Glands?

At OnElecs, our ATEX certified cable glands https://www.onelecs.com/product-category/atex-ex-proof-products/atex-cable-glands-accs/

are engineered for maximum safety and durability. We offer a wide range of sizes, materials, and accessories to meet your specific needs. Pair them with our explosion proof junction boxes and lighting solutions for a complete hazardous area setup. Contact us to learn more about custom color options or OEM labeling.

Get Started Today

Ready to secure your electrical systems with waterproof explosion proof cable glands? Reach out to us at sales@onelecs.com or visit our factory in Turkey to explore our full product range and see our commitment to quality firsthand.