In industries where safety is non-negotiable, explosion proof junction boxes for hazardous areas play a vital role in protecting electrical connections. Whether you’re operating in oil refineries, chemical plants, or mining facilities, these enclosures ensure that sparks or heat from wiring don’t ignite flammable gases or dust. This guide dives deep into what explosion proof junction boxes are, their benefits, applications, and how to select the right one for your project.

What Are Explosion Proof Junction Boxes?

Explosion proof junction boxes, also known as ATEX junction boxes for petrochemical industry, are specially designed enclosures that house electrical connections in hazardous environments. They are built to contain any internal explosion or spark, preventing it from igniting the surrounding atmosphere. Typically constructed from heavy-duty materials like cast aluminum or stainless steel, these boxes meet stringent safety standards such as ATEX, IECEx, and UL certifications.

Benefits of Using Explosion Proof Junction Boxes

Why invest in durable explosion proof junction boxes? Here are the key advantages:

Enhanced Safety: Prevents ignition in explosive atmospheres, protecting workers and equipment.

Corrosion Resistance: Ideal for harsh environments like offshore platforms, where saltwater exposure is common.

Versatility: Available in various sizes (e.g., 150x150x100 mm to 400x400x200 mm) to accommodate different wiring needs.

Longevity: Built to withstand extreme temperatures (-40°C to +70°C) and physical impacts.

Where Are Explosion Proof Junction Boxes Used?

These enclosures are indispensable in high-risk industries:

Oil and Gas: Used in drilling rigs and refineries to house wiring for control systems.

Chemical Plants: Protects connections in areas with volatile solvents or gases.

Pharmaceutical Manufacturing: Ensures safety in facilities handling flammable powders.

Grain Processing: Prevents dust explosions in silos and mills.

For example, a petrochemical plant in the North Sea recently upgraded its control systems with our explosion proof electrical junction boxes, reducing downtime by 15% due to their reliable performance in harsh conditions.

How to Select the Right Explosion Proof Junction Box

Choosing the best junction box requires careful consideration:

Hazardous Area Classification: Identify the zone (e.g., Zone 1 or Zone 21) to ensure the box meets the required safety standards.

Material: Stainless steel is ideal for corrosive environments, while aluminum is lighter and cost-effective.

IP Rating: Look for at least IP66 for dust and water resistance—essential for outdoor applications.

Terminal Capacity: Ensure the box can accommodate the number of terminals you need (e.g., 4 to 20 terminals).

Mounting Options: Wall-mounted or pole-mounted options provide flexibility for installation.

Installation Tips for Explosion Proof Junction Boxes

Proper installation is key to maximizing safety:

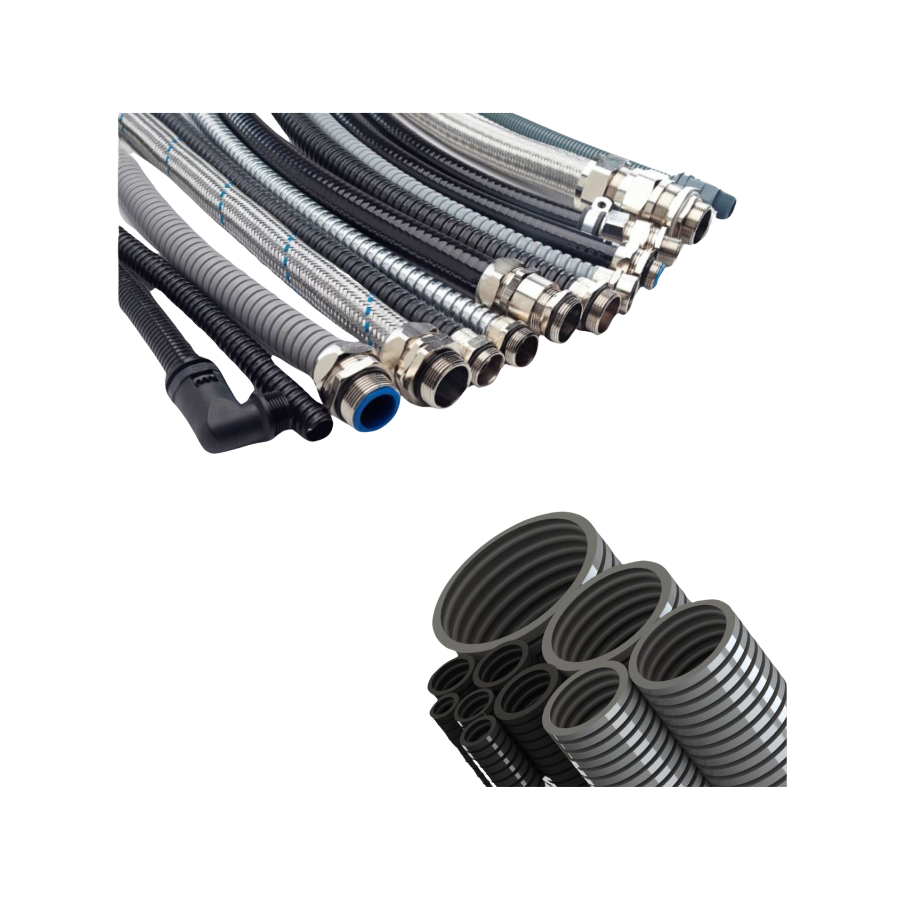

Use Certified Accessories: Pair with explosion proof cable glands to ensure a secure seal.

Grounding: Always ground the enclosure to prevent static electricity buildup.

Regular Inspections: Check seals and gaskets annually to maintain IP rating integrity.

Avoid Overcrowding: Leave enough space inside the box to prevent overheating.

Why Choose Our Explosion Proof Junction Boxes?

At OnElecs, we pride ourselves on delivering ATEX junction boxes for petrochemical industry that combine safety, durability, and customization. Our junction boxes are tested for extreme conditions and can be tailored to your specific requirements, including custom sizes and terminal configurations. Explore our full range of hazardous area solutions, including explosion proof lighting and cable glands, to complete your setup.

Contact Us Today

Looking for reliable explosion proof electrical junction boxes? Reach out to us at sales@onelecs.com or schedule a visit to our factory in Turkey to see our production process and discover how we can support your safety needs.